We are committed to the highest levels of product quality across all of our businesses. We strive to set industry standards in reliability and customer satisfaction. We aim to help our customers improve their manufacturing processes through our own process excellence. We believe that operating with higher quality standards creates a win-win situation, which leads to a competitive advantage and deep customer loyalty.

* based on a multi-site agreement and excluding sites acquired in the last 2 years

For the full Quality Document See HERE

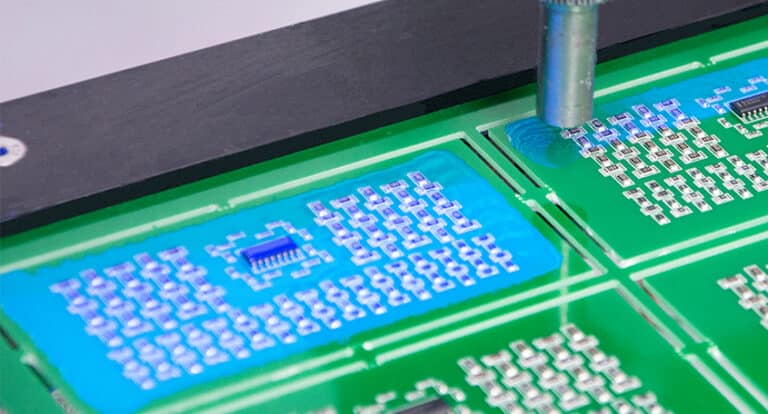

Ensuring Quality by Design

We develop our new product designs according to a multi-faceted stage-gate process. Our design process starts with the initial screening of business needs, followed by feasibility, planning, development, testing and validation. Each phase consists of a set of defined evaluation criteria dictated by both external regulatory requirements and our internal high-quality standards. This robust product development process allows us to be confident that products reach our customers with effectiveness and reliability assured.

Managing Quality

Our sites around the world are held to a consistent and independently verified standard of quality excellence. 100% of our manufacturing facilities operate with quality management systems that are certified to ISO 9001 and/or IATF 16949 under multisite agreements with LRQA, our worldwide accredited registrar. Facilities supplying our automotive customers are also certified to the International Automotive Task Force (IATF) 16949:2016 standard, which defines the QMS requirements for the automotive sector. The main tenants of our system include a thorough supplier management and scoring process, robust manufacturing controls, inspection of all finished goods with optimal quality control practices and controlled test methods, full lot traceability, sample retention and strict packaging and labelling standards.

Measuring Quality

We hold our employees to a standard of excellence where the delivery of innovative products, services and customer experiences consistently exceed industry expectations. We measure and monitor quality through several metrics, with the most comprehensive being Perfect Order Performance (POP). The American Productivity and Quality Center (APQC) defines POP as flawlessly taking and fulfilling a customer order, which includes taking the order correctly, allocating inventory immediately, delivering the product on time and sending an accurate invoice. We have a POP target of 95% across all of our facilities based on benchmarking data from the APQC. Our POP for the last two years averaged 94.2%. This performance is primarily attributable to supply chain disruptions related to COVID-19, which impacted our on-time deliveries.

We also track customer complaints. Less than 0.2% of product shipments received Type 1 complaints related to product performance in both of the last two years.