Written by Electrolube’s French Technical Sales Engineer:

The ‘phone call came through during the first week of March. The caller, Alexandre Boullot, Managing Director of Odeli – On Demand Lighting (French LED specialist responsible for designing bespoke lighting solutions).

A young and energetic company, Odeli have three bywords for success: Quality, Innovation and Reactivity. The reason for their call? They had just won an urgent contract, and needed an immediate solution – yesterday, if possible.

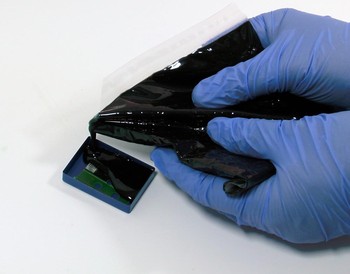

Odeli needed to encapsulate an LED system with resin and immediately thought of Electrolube with our extensive range of solutions for the LED market including conformal coatings, encapsulation resins and thermal management products. Our mantra of ‘let’s talk solutions and we love problems’ was about to be put to the test in spectacular style and with my customer… no pressure whatsoever then!

My first priority is always to understand the individual customer needs and work out a specification list taking into consideration all aspects of the environment, application process and product characteristics.

Odeli required a resin with 3 key characteristics:

Protection

Absolutely the primary issue; the nature of the environment (outdoor stadium) meant that the potted LED systems needed to protect to the electronic device from the weather and also dust and sand particles etc.

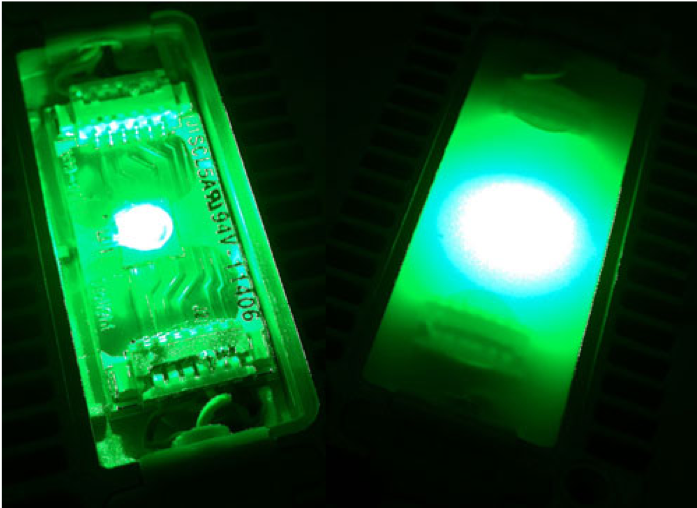

Light dispersion

The light dispersion factor is also critical for the end use. An amazing quality of light dispersion is achievable by use of a hazy resin solution. The light can pass through, but is also dispersed rather than emitting a harsh beam.

Aesthetics

Last, but not least, aesthetics. Gone are the days when a potting compound is merely functional. The exponential growth and drive in the LED market requires aesthetic solutions combining function with design. Fortunately the development chemists at Electrolube had already planned ahead for this trend and could offer a drop-in solution.