In recent months, I have encouraged the readership to take a closer look at Conformal Coating problems, particularly those that circuit designers could address at the earliest stages of a project. In a recent column, I also offered advice on how to identify some of the potential pitfalls that could sabotage your coating process. In this, my latest piece, I’m going to take a look at some issues you are sure to face; from areas of the coated board that simply refuse to cure fully, masking components, the orange peel effect and examining the difference between a critical and a non-critical area of a board.

1) What kills coating quality and cycle time on a typical selective coating line?

Selective coating machines deposit a stripe of coating material, that can be programmed to stop and start on demand. Stripes of coating can be deposited to create a coating pattern, avoiding areas such as switches, connectors and test points which must not be coated to prevent interference with form, fit or function. The coating stripes deposited are usually in the 8-15mm range, for optimum accuracy and minimizing overspray and splashing. When the area to be coated is less than 8mm in width, then it is necessary to utilise a dispensing step, which is a cycle time killer.

Due to the combination of machine X/Y positional accuracy, material fluid dynamics and component topography, 2-3mm is usually as close to keep out areas as anyone would be comfortable coating for a repeatable process. So must coat and keep-out areas within 2-3 mm of each other present a problem and again dispensing will be required, another process step which kills cycle time.

2) Why would you need to mask some components/area of the board?

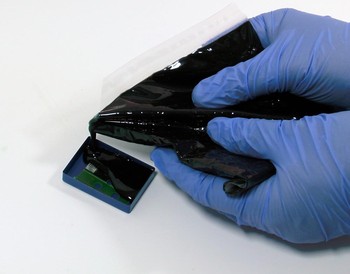

Some areas of the board, such as test points may need to be masked to avoid the application of coating, to enable functional testing after coating. Other areas may need to be masked to prevent obscuring labels for example, essentially wherever the application of coating is undesirable from a form, fit or function point of view. In the case of unsealed connectors, switches etc, the main issue is the coating ‘wicking’ up and coating the connector mating surfaces, thus reducing the contact or potentially insulating the mating surface, preventing either the form, fit or function of the connector or switch.

3) Can you please explain ‘orange peel effect’ in more detail? I.e. where does it come from? Why does it happen, can it cause board failure or have other detrimental effects?

Orange peel is a cosmetic defect, in which the appearance of the coating surface can appear matted and mottled under the correct lighting conditions, resembling the peel of an orange (hence the name). However, orange peel is poorly understood and often used, incorrectly, to describe a host of other cosmetic and functional defects.

True orange peel is primarily an issue with coatings that dry by solvent evaporation. During the drying of a solvent-borne coating film, the solvent at the surface evaporates, causing differences in temperature, surface tension, solvent concentration and density within the film. To balance the newly formed thermodynamic non-equilibrium, currents occur in the coating film. These currents produce eddies in the drying layer, a phenomenon known as the formation of Bénard cells. The surface tension is higher at the edges of the cells than at their centres and coating material flows from regions of lower surface tension to regions of higher surface tension. The resulting unevenness in the surface dries into the coating film. This produces an irregular surface as the coating shows marked texture resembling the peel of an orange under normal lighting conditions.

Under UV light, however, the coating will normally appear homogenous, as long as the thickness is sufficient to cause correct fluorescence. Orange peel is exacerbated in coatings that dry quickly, and especially when applied thickly. Since this effect is primarily cosmetic in nature and doesn’t really affect the long term protection offered by the coating, it has been removed as a defect from various inspection guidelines. Applying the coating in the correct thickness range, and replacing very fast drying solvents in the formulation with slower drying solvents, will largely eliminate these issues.

Sometimes the formation of tiny bubbles of micro-foam in the surface of the coating can cause a matting effect and be confused with orange peel, but these can usually be seen under magnification, especially under UV light and are usually the result of a change in spray pressure or a change in the curing profile. These tiny bubbles can usually be ignored as a cosmetic finish, unless they are bridging conductor spacings or exposing metal surfaces. Any instance where the material does not fluoresce continuously is not orange peel, and is likely to be de-wetting due to contamination.

4) What is the difference between a critical and a non-critical area of a board?

Typically, during design and development, engineers will evaluate the robustness of their board design and prototypes. They will determine that certain areas of the board, or components, are critical to performance and more susceptible to failure than other areas, and will concentrate their coating or protection strategies on these critical areas. These will often be denoted as ‘MUST COAT’ areas. Areas of the board that MUST NOT be coated, including connectors, switches, test points or any other area that will affect form fit or function will be denoted as MUST NOT COAT areas. The remaining areas will preferably be marked up as DON’T CARE areas of the board. This helps simplify the coating of the assembly by focussing on what is most important to the successful coating operation.

5) How is it possible that some areas of a coated board may never cure fully?

There are several reasons why conformal coating in some areas of a coated board may never fully cure, each depending upon the cure chemistry. With water-based materials for example, a film develops as the water evaporates but the drying process can take an extremely long time, which can increase exponentially with applied thickness. If the material gets underneath a component and the component is tented with coating material, the material will dry much faster at the component leads and may actually impede the subsequent drying of the material beneath the component. The evaporating water cannot readily pass through the tent, so there is no kinetic driver for the remainder of the water to evaporate and the coating will remain conductive.

With UV curable materials, the primary reaction mechanism is initiated by UV radiation of suitable wavelength and intensity. Light only travels in straight lines and due to the 3D topography of a typical PCB, and tendency for material to wick beneath components, there will always be areas that don’t see the UV radiation. To try and overcome this issue, formulators include a secondary cure mechanism, usually moisture initiated. The issue is similar to water-based, in that very often the coating material will have cured around the component, which was exposed to the UV light. If the coating is a good barrier to humidity (which you would hope from a conformal coating) then it can take a very, very long time for moisture to diffuse through and initiate the secondary curing mechanism. Even if this happens, 50-70% of a typical formulation will not be involved in the moisture reaction and the product ‘cured’ by the secondary mechanism only, will have very different properties to the bulk material.

The platinum catalyst used in certain heat-cured silicone materials is very sensitive to the presence of contaminants on the board, which can poison the catalyst and prevent cure. These contaminants include many amines and halides, flux acids and other chemicals widely used in electronics assembly. Cleaning, cleanliness and process control become very important with these types of material.

It’s no easy task choosing the correct conformal coating for your product, let alone have confidence that in applying it, you will have achieved the ultimate goal of protecting your electronics. Conformal coatings are available in many generic types and each type has its strengths and weaknesses. Choose the right coating for your intended use and operational environment, rather than one that is used by your subcontractor or qualified on another product line for a different end-use environment. And, most importantly, be sure to test your design to ensure that it has sufficient robustness for the intended application. Just because a coating has an industry standard approval, doesn’t mean that this will solve your coating needs. Testing is key to knowing what your material can and can’t do.

If you have any questions, or would like more information about choosing and/or applying conformal coatings, then there’s a wealth of experience to call upon from our Technical Support Team members who will be more than happy to answer your queries and offer expert guidance. Look out for my next column where I will be looking at more coating related tips.