Global electro-chemicals manufacturer, Electrolube, is planning a major attraction on its stand (A4-466) at Productronica this year with live demonstrations of its new range of UV cure conformal coatings, one of the most anticipated new group of coating products to come to market in recent years. Electrolube’s new series of coatings enable immediate board-handling with full cure guaranteed within an impressive 6-12 hours due to the chemical secondary cure mechanism. One of the biggest advantages of the new range is its capability to vastly reduce production time. Most systems can take between 8 to 14+ days and even longer in many cases, whereas Electrolube’s UV coatings fully cure in less than 12 hours.

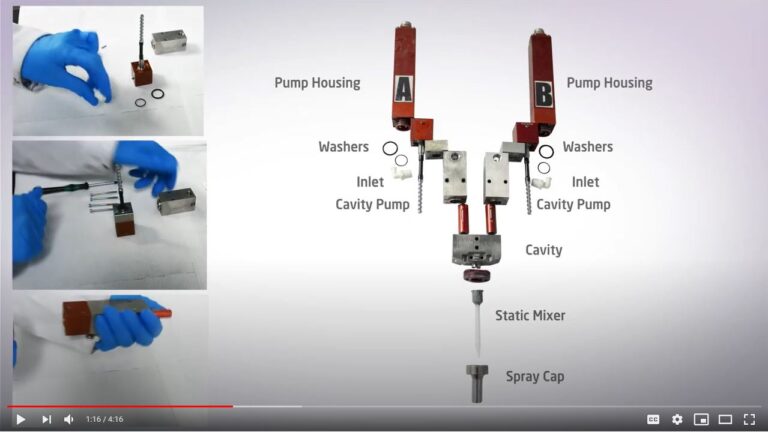

Visitors will have the opportunity to watch live demonstrations of the UV cure coatings being dispensed using the latest selective coating systems from PVA and Asymtek, and cured with a UV cure oven. Visitors will also be able to discuss applications with Electrolube’s senior experts and withness the company’s high-tech solutions first hand. Electrolube and its process equipment partners have invested considerable time and effort to mount these demonstrations and the company is confident that they will prove a major draw to its stand this year.

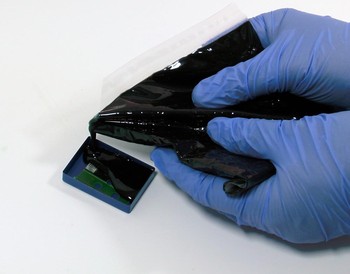

The UV range comprises six next generation UV cure conformal coating products, which are solvent-free, VOC-free and provide unrivalled performance in harsh environments, including high resistance to cracking during thermal shock cycling. The range features UVCLP, a ‘Plus’ version of UVCL. It is a transparent, flexible coating which is extremely resistant to thermal shock and offers improved coverage and protection, along with a guaranteed chemical cure in 6 hours thanks to its unique secondary cure mechanism. There is also an an ‘xtra’ version of UVCL, called UVCLX, which shares the benefits of UVCL-P and increases ease of inspection. UVCLX is a green-opaque coating that can be applied at up to 300 microns and has a higher maximum operating temperature of 150°C.

An additional product launch, UVCL-FC enables the application of an even thinner coating facilitating faster curing time and reducing WIP. UVCL-HV is a high viscosity UV curable material, designed to provide better coverage of component leads and exposed metal surfaces during dispensing applications and Electrolube’s UVCL-Gel is a no-flow gel version of UVCL, designed for sealing connectors and other areas that must not be coated.

UVCL is a single component, medium-low viscosity dual cure coating with secondary moisture cure, ensuring complete cure in shadow areas.

Ron Jakeman, Managing Director of Electrolube, comments, “We are excited to launch our innovative new UV range at Productronica this year. Electrolube’s new launches offer significant advantages over first generation UV cure coatings, providing even higher levels of performance and drastically reduced WIP. We are looking forward to engaging with visitors on the stand and listening to their feedback about the live demonstrations, which will take the new material through dispensing and curing. The UV range is a real game-changer and as we prepare to demonstrate its rapid-curing properties, we anticipate a lot of interest in this coating at the show.”